Professional Packaging Machine Repair Service to Keep Your Devices Running Efficiently

Professional Packaging Machine Repair Service to Keep Your Devices Running Efficiently

Blog Article

Comprehending the Key Components and Repair Work Techniques for Packaging Device Maintenance

Effective maintenance of product packaging equipments hinges on a complete understanding of their key parts, including the framework, drive system, and securing systems. Acknowledging typical upkeep problems, paired with the execution of preventative techniques and repairing strategies, can considerably improve maker dependability. The option of repair service methods, consisting of the use of OEM components and the significance of certified specialists, plays a crucial role in minimizing downtime. To absolutely understand the details of these systems and their maintenance, one should take into consideration the wider implications of neglecting these essential techniques.

Secret Elements of Packaging Equipments

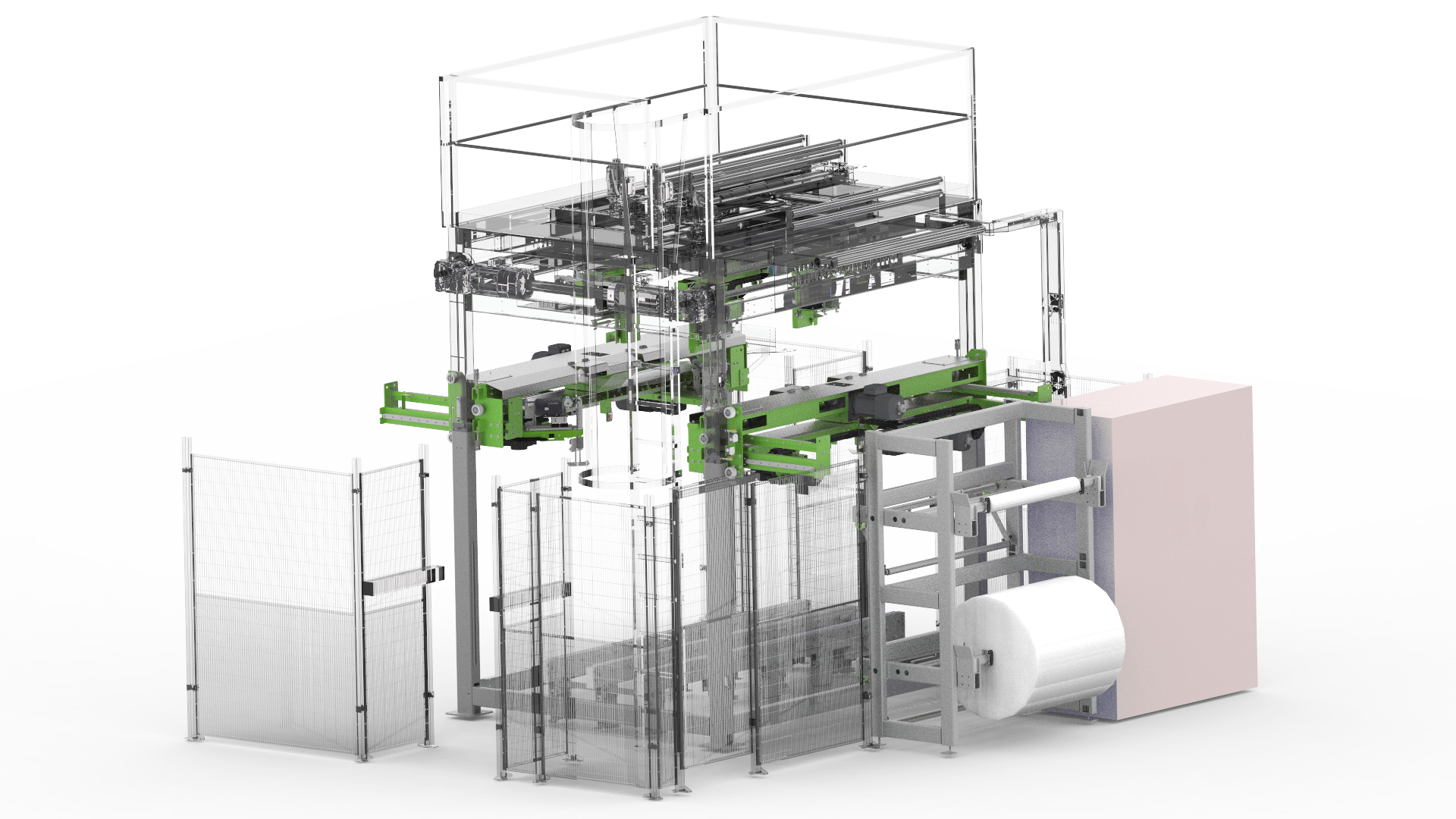

Product packaging equipments include a number of vital components that function with each other to ensure efficient and effective product packaging procedures. At the core of these machines is the frame, which provides architectural honesty and houses the numerous operating components. The drive system, frequently a mix of motors and gears, promotes the motion of components, making it possible for exact procedure throughout the product packaging cycle.

Another important part is the conveyor system, which transports items via different phases of the packaging process. This is frequently enhanced by sensing units and controls that keep track of the placement and rate of things, ensuring synchronization and minimizing mistakes. The filling up system is vital for accurately giving the best amount of product right into packages, whether in fluid, powder, or strong type.

Securing devices, including warm sealants or glue applicators, play a crucial duty in securing packages, avoiding contamination and prolonging life span. Additionally, labeling systems are indispensable for giving needed product info, guaranteeing compliance with guidelines. Lastly, the control panel, outfitted with straightforward interfaces, enables operators to manage maker features, monitor efficiency, and make adjustments as required, ensuring optimal performance and effectiveness in packaging procedures.

Usual Maintenance Concerns

Efficient procedure of packaging equipments relies heavily on routine upkeep to stop usual problems that can interfere with manufacturing. Among these issues, mechanical deterioration prevails, particularly in elements like seals, conveyors, and motors, which can result in unexpected downtimes. Additionally, imbalance of components can cause inefficient operation, creating products to be incorrectly packaged or harmed during the procedure.

One more common upkeep concern involves the buildup of dust and particles, which can disrupt the machine's sensing units and relocating parts. packaging machine repair service. This not just influences performance however can additionally present security dangers. Furthermore, lubrication failings can result in boosted rubbing, causing overheating and ultimate part failure.

Electrical problems, frequently stemming from loosened connections or damaged wiring, can disrupt machinery features, resulting in substantial production delays. Software application problems due to incorrect setups or obsolete programs can hinder the machine's operation, necessitating prompt treatment. Attending to these common upkeep issues proactively is important for making certain optimum performance and long life of product packaging equipment.

Preventative Upkeep Approaches

Executing preventative maintenance strategies is essential for maintaining the effectiveness and reliability of product packaging equipments. These techniques encompass a methodical method to maintenance, concentrating on the regular examination and servicing of devices to preempt prospective failings. By adhering to an arranged maintenance program, operators can recognize wear and tear on components prior to they cause significant malfunctions.

Crucial element of a navigate to these guys preventative maintenance strategy consist of regular examinations, cleaning, lubrication, and component replacements based on supplier suggestions. Using checklists can enhance this procedure, making sure that no important tasks are ignored. Additionally, keeping accurate documents of maintenance activities help in tracking the maker's performance with time, assisting in informed decision-making pertaining to future upkeep demands.

Training team on the value of preventative maintenance enhances compliance and fosters a society of aggressive care. Applying an anticipating upkeep part, making use of information analytics and sensing unit modern technology, can even more maximize equipment efficiency by anticipating failings before they take place.

Troubleshooting Techniques

When confronted with breakdowns or inadequacies in packaging machines, utilizing organized troubleshooting methods is necessary for recognizing and settling concerns swiftly. The initial action in effective troubleshooting is to establish a clear understanding of the machine's functional criteria and performance metrics. This involves assessing the maker's requirements, in addition to any mistake alerts or codes displayed.

Following, drivers need to carry out an aesthetic inspection, examining for evident indications of imbalance, wear, or damages. This usually includes checking out sensing units, belts, and equipments to determine potential root causes of breakdown. Collecting functional information, such as manufacturing rates and downtime logs, can also provide understandings into recurring concerns.

Once prospective troubles are recognized, making use of a rational strategy to isolate the root cause is important. This may call for screening individual components or systems in a regulated way. Involving browse around this site in discussions with drivers who interact with the equipment on a regular basis can yield beneficial responses concerning unusual actions or patterns.

Repair Work and Replacement Best Practices

A thorough understanding of repair work and substitute best methods is important for maintaining the longevity and effectiveness of packaging makers. Regularly evaluating the condition of machine components permits timely intervention, stopping even more substantial issues that can result in costly downtimes.

When fixings are essential, it is essential to make use of OEM (Original Equipment Manufacturer) parts to make certain compatibility and performance. This not only preserves the integrity of the device but likewise maintains service warranty arrangements. In addition, it is suggested to keep a stock of critical extra components to assist in quick replacements and minimize operational interruptions.

For intricate fixings, involving qualified professionals with specialized training in packaging machinery is recommended. They have the know-how to detect problems precisely and execute repairs successfully. Recording all fixing tasks and parts replacements is crucial for keeping a thorough upkeep history, which can assist in future troubleshooting.

Finally, executing an aggressive approach, including regular inspections and anticipating maintenance strategies, improves the reliability of packaging machines. By sticking to these finest techniques, services can ensure ideal machine performance, reduce functional threats, and expand devices life-span.

Verdict

In conclusion, a detailed understanding of packaging maker elements and reliable upkeep methods is vital for ideal efficiency. Routine assessments and the use of OEM parts can considerably reduce downtime, while a well-documented maintenance history promotes aggressive treatment. Employing certified service technicians further enhances repair work quality and dependability. By executing these methods, companies can make sure the durability and effectiveness of product packaging makers, inevitably adding to boosted operational productivity and minimized prices.

Effective maintenance of packaging devices hinges on a thorough understanding of their vital parts, including the frame, drive system, and sealing mechanisms.Effective operation of product packaging equipments relies greatly on normal maintenance to stop typical concerns that can interfere with manufacturing.Applying preventative upkeep techniques is vital for maintaining the effectiveness and dependability of product packaging makers. Additionally, maintaining exact documents of upkeep tasks aids in tracking the maker's efficiency over time, assisting in informed decision-making pertaining to future maintenance demands.

Report this page